Thrust roller bearings are used to bear the combined axial and radial load, which is mainly the axial load, but the radial load shall not exceed 55% of the axial load. Compared with other thrust roller bearings, this type of bearing has a lower friction factor, higher speed, and has self-aligning performance.

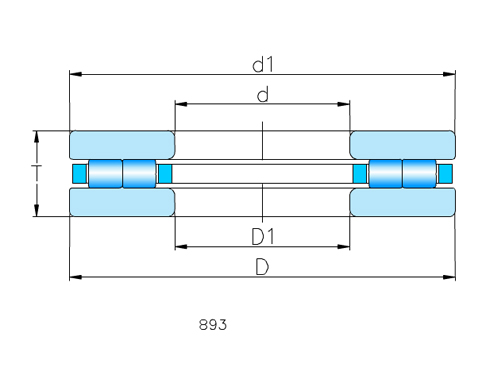

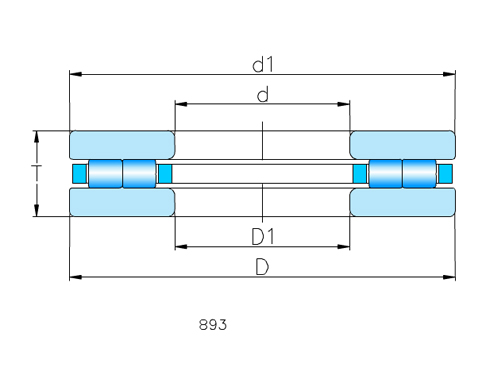

Thrust cylindrical roller bearings and thrust tapered roller bearings are suitable for low speed occasions, thrust tapered roller bearings have a slightly higher speed than thrust cylindrical roller bearings. Thrust cylindrical roller bearings are separable bearings, which can only bear one-way axial load and slight impact, and can limit the axial displacement of the shaft (or housing) in one direction, so it can be used for one-way axial positioning. But its carrying capacity is far greater than that of thrust ball bearings. When the roller is rolling, due to the different linear speeds at the two ends of the roller, the roller will inevitably slide on the raceway of the ring. Therefore, the limit speed of this type of bearing is lower than that of the thrust ball bearing, and it is usually only suitable for low-speed operation.

The standard design of thrust cylindrical roller bearing adopts a car-made metal solid cage. According to user requirements, cages of other types or materials can also be used. Thrust tapered roller bearings can only bear one-way axial load and can limit the one-way axial displacement of the bearing, so it can be used for one-way axial positioning. Compared with thrust cylindrical roller bearings, the bearing capacity is large, the relative sliding is small, but the limit speed is lower.

Chinese

Chinese German

German